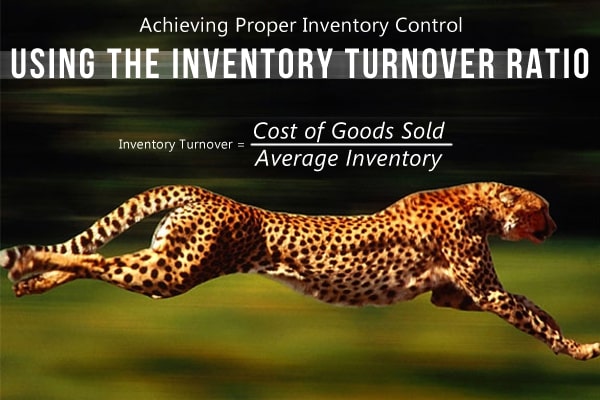

Achieving Proper Inventory Control Using The Inventory Turnover Ratio

For many different companies in the Philippines, most especially outsourcing companies, speed is the game we have to play. As business owners, it is crucial for us to keep up if we want to catch up with good business and run away from a bad one. Speed can mean many good things for us, like how fast our products are selling or how fast a project is finished. However, with too much speed we can go out of control. Unfortunately, this usually happens with manufacturing or retail companies that produce excess inventory. In the end, they sell too little. There is no need to worry though because there is a way we can tame a crazy speedster. This is through calculating our Inventory Turnover Ratio.

What is Inventory Turnover Ratio?

To put it simply, it is like a scale. One side has what we call Cost of Goods Sold, and the other has our Average Inventory.

When the Cost of Goods Sold tips further down than the Average Inventory, it can mean we are selling a lot of products, but manufacturing too little at a time. This can result in a gradual disinterest in the product since it takes too long to be in stock.

When it is the other way around, we have too much products that are not selling as fast as we would want them to sell. Eventually, we might not have enough money to manufacture new products. We then end up stuck with old-stock products that might not be as desirable.

Achieving balance or a good ratio is essential in keeping a good business. However, having too much or too little is sometimes okay in some situations. For example, for a big retail store or grocery store, having a lot of inventory is okay, but it is still better to make sure they are growing inventory purchases too.

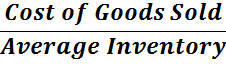

What Is The Formula?

To get the Inventory Turnover Ratio, we have to divide the Cost of Goods Sold by the Average Inventory. Here is an illustration:

Inventory Turnover =

How Do We Know We Have A Good Ratio?

Generally, when a business has a high turnover ratio, it means they are spending and manufacturing just enough to keep up with demand. A low turnover ratio often means a business is over-stocking, but not selling as fast as it wants to. That being said, higher inventory turnover ratios should always be the goal for businesses.

However, like I said earlier the goodness or badness of an Inventory Turnover Ratio result is situational. Sometimes a high ratio can even mean we are actually losing business. To have a clearer idea, here is the opinion of an expert on Inventory Turnover Ratio:

“In an ideal world, you, the retailer, has every item that every customer walking through the door wants, and you don’t have to pay for it until the customer buys it. In the real world, it’s a challenge to have the right mix of products for your customers. You can’t possibly have everything that every customer wants. A high inventory turnover ratio might indicate that you’re losing sales. Imagine a bike shop that just sells tubes. They might have a high turnover ratio because they sell tubes without a large inventory, but they’re probably losing tire sales.”- Bradley Saul from www.lightspeedretail.com.

The key here is to know the nature of our business and know it well! That way, we can make our own assessments of whether a low or a high turnover ratio is good, bad, or just okay.

Why Is It So Important?

Remember, speed is essential in a business, and this is a faster way for us to assess how efficiently our business is controlling our inventory. We can clearly see the relationship of our costs and our inventory turnover rate, and who does not want to know that?

By regularly calculating our Inventory Turnover Ratio, we know if our business is too fast or too slow. Are we fast enough for our figurative Cheetah to catch the yummiest Gazelle? Or are we too fast that we are unable to notice a cliff up ahead? A controlled speed is so much better, so we do not get carried away, trip, and fall off that cliff.

Comment 0